Imperceivable Innovations

Printing technology on the nano scale

According to the U.S. Organ Donation & Transplantation System, more than 100,000 patients are awaiting organ transplantation, with roughly 16 people dying per day on the waiting list. Patients with advanced kidney disease make up approximately 87% of these cases.

With 3D Nano Printing, this could all change. In the future, patients could be diagnosed with liver failure and have a new liver printed from their own cells, then transplanted without ever going on a waiting list.

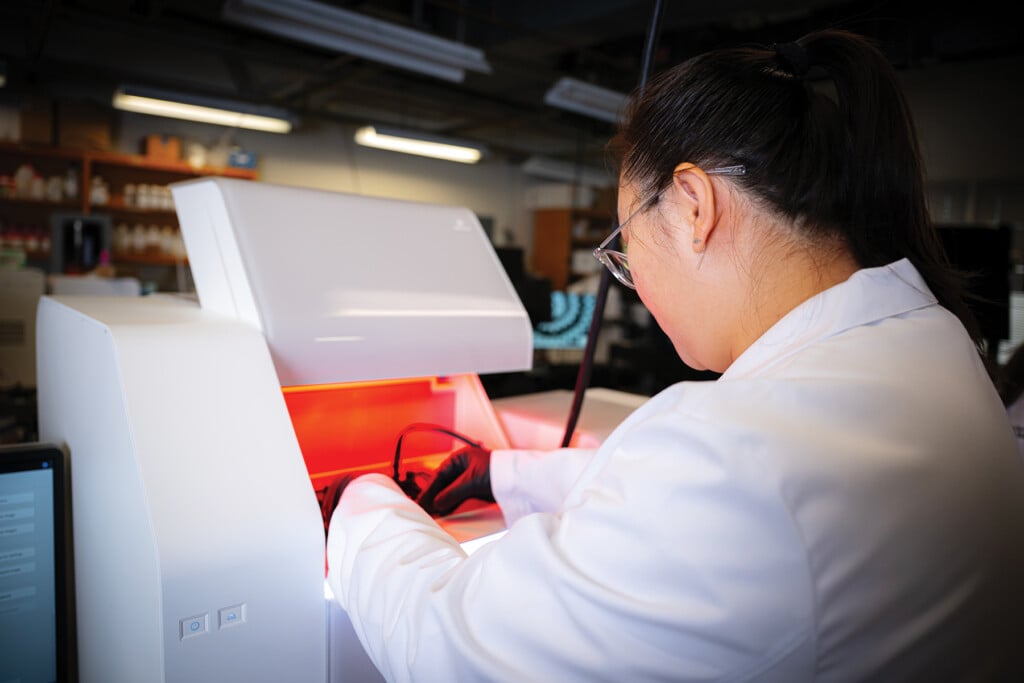

Though the technology capable of this level of precision and scale has not yet been created, researchers like Jamel Ali are working on projects that may pave the way for this sort of medical innovation.

Ali is an assistant professor in the Department of Chemical and Biomedical Engineering in the National High Magnetic Field Laboratory (MagLab) as part of the FAMU-FSU College of Engineering. According to Ali, his team is using “3D printing to develop tissue models for studying cancer, working with Mayo Clinic on products related to glioblastoma and other cancers. And we’re also 3D printing tissues to model the human liver, or the hepatic tissue.”

This work will help with preclinical testing. Ali explained that “over 70% of drugs developed fail clinical clearance, not because the drugs don’t do the job, but because it’s toxic to the liver because of their hepatotoxicity. We want to make better in vitro models for screening drugs.”

Rather than using animal models and small-scale human trials to test the viability of drugs at the preclinical stage, organoid models using human derived cells could be more informative and less costly than current methodology.

The truly remarkable feat here is that Ali is producing these small-scale organoids capable of replicating aspects of the liver. Right now, they are laying the groundwork for experimentation in murine models, but eventually, Ali says, “We implant that into a person one day that has a dysfunctional liver.”

Though not currently viable for use in humans, the ultimate goal is to restore functionality in patients with damaged livers.

Another application that Ali’s lab is using 3D nano printing for “is to make micro, nanoscale actuators, or as we like to call it, a lot of micro nanoscale robots—bacterial-like structures with these printers that are then magnetized and able to be actuated using external magnetic fields and field gradients so that we can get them to do things maybe one day in our bodies,” Ali says, such as deliver drugs, act as diffusion barriers, medical imaging, and minimally invasive biopsies.

Outside of biology, Ali says, “Our lab is interested in creating nonmetallic, non-biological applications. Engineered biofilms are applications of interest to the Department of War.”

Ali is also working with Professor Subramanian Ramakrishnan from the Department of Chemical and Biomedical Engineering at FAMU-FSU College of Engineering to design advanced materials for in-space manufacturing by utilizing innovative printing methodologies. With limited resources in space, broken equipment or a cracked shield can be catastrophic. But, Ali says, “If you’re printing with living things that have optical properties, basically now you have systems that are potentially self-healing,” which would prove an invaluable material on space missions.

Erika Bechtold, vice president of U.S. operations for UpNano, who produces one of the world’s leading 3D nano printers, attributes these advances to the ability to upscale 3D printing, which is a core mission of UpNano.

“Let’s try to make it easy. Let’s try to really help individual labs and core facilities get these nanoscale 3D printers and be able to really have them become mainstream,” Bechtold says. “We can also 3D print the optics that are inside the camera lenses.”

The potential to create lenses on the nanoscale would drastically improve our diagnostic capabilities, making procedures less invasive for patients. In general, increasing the number of labs capable of conducting nano research and print on the nanoscale will naturally increase the number of innovations across disciplines. Scientists around the globe are making strides toward advancing our capabilities with these technologies. Vaccine delivery could take place with microneedles. We could also create smaller cell phones and other imaging technologies.

In time, these tiny building blocks will reshape every aspect of humanity. ▪

Zooming In

A nanometer nm is 1 billionth of a meter, a size far too small for a human to detect. The smallest particle a human can see floating in the air in the best possible light is 10,000 nm across.

For a frame of reference, a human hair is roughly 90,000 nm thick, approximately the same width as a piece of paper, which is 100,000 nm wide. A single human cell can be as wide as 10,000 to 30,000 nm, visible as a particulate to the naked eye.

The minimum resolution for 3D nano printing can go as low as 100 nm, which is far too small to detect with the human eye. The single strand of human DNA is about 2.5 nm wide, so the resolution is not quite small enough to create the interstitial components of a cell but is low enough to print living tissue.

→ How does it work?

Two-photon polymerization (2PP) is a cutting-edge form of 3D nanoprinting that uses extremely short laser pulses to “write” tiny structures directly into a light-sensitive material. Unlike regular 3D printing, which builds layer by layer, 2PP can also sculpt objects freely in three dimensions, focusing light so precisely that only the very center of the beam activates the material. This precision allows scientists to create features smaller than the wavelength of light, as low as 100 nm.

Using computer-controlled laser paths, researchers can form intricate lattices, microlenses, and even scaffolds for living cells. The process works by having the material absorb two photons at once, which only happens at the laser’s focal point, triggering solidification in a tiny voxel (a 3D pixel) and happens only where the light intensity peaks.

The technology is revolutionizing nanofabrication, enabling breakthroughs in micro-optics, photonics, biomedical engineering, and metamaterials. While still slower than large-scale printing, advances in laser scanning and chemistry are speeding it up, bringing us closer to mass production of custom nanoscale devices that blend the worlds of art, biology, and physics.